Die casting is a metal casting process that uses a high-precision steel mould to produce complex metal parts. The molten material, generally aluminium, zinc or magnesium, is injected into the mould under high pressure, ensuring strong and detailed components, ideal for sectors such as automotive, electronics and energy, where complex geometric shapes with reduced weight are often required.

Besoins:

Monitoring the closing force

En savoir plus

Measurement of clamping force distribution

En savoir plus

Calibration and testing of tie bar deformation

En savoir plus

Mould position monitoring

En savoir plus

Monitoring the position of the ejectors

En savoir plus

Measurement of pressure in the hydraulic circuit

En savoir plus

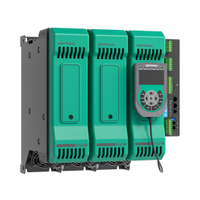

Control the electrical heaters of the holding furnace

En savoir plus

Measurement of the temperature of the holding furnace

En savoir plus

Operating principle

The die casting process is a production technique used to manufacture metal components with high precision and excellent surface finish. The main step in the process is the injection of molten metal alloys (such as aluminium, zinc, magnesium) into a preheated metal mould. The molten metal is kept at the ideal temperature by holding furnaces, which ensure its homogeneity and fluidity throughout the injection phase.

The process is divided into two main phases:

- injection of the molten metal into the mould

- cooling that leads to the solidification of the item.

Initially, the metal is melted and maintained at high temperature, before being injected at high pressure (up to 2000 bar) into the mould. The injection speed and high pressure generate strong vibrations that can affect the stability of the machine, which must therefore be designed to withstand these stresses. The pressure is also maintained during the cooling phase, so as to guarantee the correct solidification of the metal and the geometric fidelity of the component.

This process offers numerous advantages for the production of complex components for sectors such as automotive, electronics and energy, because it can be used to obtain high quality parts, with reduced tolerances and high production efficiency. In addition, it minimises waste material, optimising production costs.

Requirements and Technology

To ensure the efficient and precise production of metal components through die casting, it is essential to carefully monitor and control some critical process variables:

- Temperature of the molten metal,

- Injection pressure,

- Mould closing strength and geometry,

- Mould position.

Having the metal at a suitable temperature, which varies depending on the alloy used, is essential to maintain homogeneous and fluid melting, thus ensuring the repeatability of the process during the injection phase.

The control of pressure in the hydraulic circuit is equally important: in die casting systems, pressures may rise to up to 2000 bar, with rapid peaks that, if not detected promptly, can compromise the integrity of the components and cause serious damage.

Finally, supervising the force and the geometry of the mould during the opening and closing phases not only guarantees a high quality product, but also allows the detection of any anomalies in advance, reducing the risk of failures and expensive machine downtime.